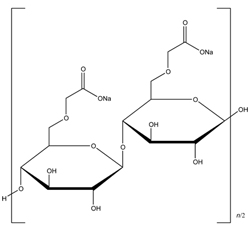

Sodium Carboxymethyl Cellulose (CMC)

Description

Daffulose, Sodium Carboxy Methyl Cellulose a Principle Product of Posy Pharmachem Pvt. Ltd., Since 1994, it serves the finest quality of products to a large number of Customers.

Daffulose – CMC is an anion type cellulose ether, white or slight yellow powder which is odourless, non poisonous, non combustible , non mouldable, solvent in cold or warm water and it results in sticky solution with good thickening , suspending Emulsifying and rheology properties. It is widely used in foods, medicines Petroleum, chemical,Textile, construction , ceramics, paper milling etc. Our Daffulose has wide range of applicability.

Our Daffulose has wide range of applicability.

Grades

| GRADE | Viscosity (25°C, 1% Aqueous Solution) CPS | Viscosity (25°C, 2% Aqueous Solution) CPS |

|---|---|---|

| FM01 | 0 – 100 | 1000 |

| FM12 | 120 – 250 | 1200 – 2500 |

| FM24 | 250 – 400 | 2500 – 4000 |

| FM812 | 800 – 1200 | 8000 – 12000 |

| FM1220 | 1200 – 2000 | 12000 – 20000 |

| FMSH20 | MIN.2000 | 20000min. |

| Properties |

| |

| Applications | As Thickener, Stabiliser, Emulsifier in

| |

| GRADE | Viscosity (25°C, 1% Aqueous Solution) CPS | Viscosity (25°C, 2% Aqueous Solution) CPS |

|---|---|---|

| TE01 | 0 – 100 | 1000 |

| TE12 | 120 – 250 | 1200 – 2500 |

| TE28 | 250 – 400 | 2500 – 4000 |

| TE812 | 800-1200 | 8000-12000 |

| TE1220 | 1200 – 2000 | 12000 – 20000 |

| TE10000 | 2000 – 10000 | 20000min. |

| Properties |

| |

| GRADE | Viscosity (25°C, 1% Aqueous Solution) CPS | Viscosity (25°C, 2% Aqueous Solution) CPS |

|---|---|---|

| CR01 | 0 – 100 | 1000 |

| CR12 | 120 – 250 | 1200 – 2500 |

| CR28 | 250 – 800 | 2500 – 4000 |

| CR812 | 800 – 1200 | 8000 – 12000 |

| Properties | CMC immediately causes the glaze to settle like cement. The glaze is solid, hard lump in the bottom of the bucket. CMC causes the glaze to stay in suspension. | |

| Application |

| |

| GRADE | Viscosity (25°C, 1% Aqueous Solution) CPS | Viscosity (25°C, 2% Aqueous Solution) CPS |

|---|---|---|

| CM01 | 0 – 100 | 1000 |

| CM12 | 120 – 250 | 1200 – 2500 |

| CM24 | 250 – 400 | 2500 – 4000 |

| CM812 | 800 – 1200 | 8000 – 12000 |

| CM1220 | 1200 – 2000 | 12000 – 20000 |

| Properties |

| |

| Application |

| |

Specifications

| Tests | Specifications |

|---|---|

| Description | White to cream -colored powder or granules. Hygroscopic |

| Solubility | It is easily dispersed in water to form colloidal solution. Insoluble in alcohol, in ether, and in most other organic solvents. |

Identification

| (A) A red-purple color develops at the interface. (B) A fine, white precipitate is formed. (C) A dense precipitate is formed. |

| pH | 6.5-8.5 in a solution (1 in 100). |

| Viscosity | Not less 75% and Not more than 140% of the declared value. |

| Heavy metals | Not more than 20 ppm |

| Loss on drying | Not more than 10.0%, dry at 105° C for 3 hours. |

| Assay | Not less 6.5% and Not more than 9.5% of sodium (Na), calculated on the dried basis. |

| Tests | Specifications |

|---|---|

| Appearance | A white or almost white, granular powder, hygroscopic after drying. |

| Solubility | Practically insoluble in acetone, in ethanol and in toluene. It is easily dispersed in water giving colloidal solutions. |

| Identification | A. A blue, cotton-like precipitate is formed. B. No precipitate is formed. C. The solution prepared from the sulphated ash in the test for heavy metals gives the reactions of sodium. (a) A dense white precipitate is formed. (b) No precipitate is formed. |

| Appearance of solution | Solution S is not more opalescent than reference suspension III (2.2.1) and not more intensely coloured than reference solution Y6 (2.2.2, Method II). |

| pH (1%w/v solution) | The pH of solution S is 6.0 to 8.0 |

| Apparent viscosity | The apparent viscosity is not less than 75 per cent and not more than 140 per cent of the value stated on the label. |

| Sodium glycollate | Not more than 0.4% |

| Chloride | Not more than 0.25% |

| Heavy Metals | Not more than 20 ppm |

| Loss on drying | Not more than 10.0% |

| Sulphated ash | 20.0% to 33.3% |

| Assay | 6.5 % to 10.8 % of sodium (Na), calculated with reference to the dried substance. |

| Tests | Specifications |

|---|---|

| Description | A white or almost white, granular powder; odourless or almost odourless; hygroscopic. |

| Solubility | Practically insoluble in acetone, in ethanol, in ether and in toluene. It is easily dispersed in water forming a colloidal solution. |

| Identification (A) |

A blue, cotton-like precipitate is produced. |

| (B) | No precipitate is produced. |

| (C) | Solution A gives the reactions of sodium salts. (a) dense, white precipitate is formed. (b) A yellow crystalline precipitate is formed. |

| Appearance of solution | Solution A is not more opalescent than opalescence standard OS4 and not more intensely coloured than reference solution YS6. |

| pH | 6.0 to 8.0 determined in solution A. |

| Apparent viscosity | 75 to 140 per cent of the declared value, |

| Arsenic | Not more than 1 ppm |

| Heavy metals | Not more than 20 ppm |

| Chloride | Not more than 0.25 per cent |

| Sulphated Ash | 20.0 to 33.3 per cent, calculated on the dried basis, determined on 1.0 g |

| Loss on drying | Not more than 10.0%, determined on 1.0 g by drying in an oven at 105°C. |

| Assay | Not less than 6.5% and not more than 10.8% of Sodium, Na, calculated on the dried basis. |